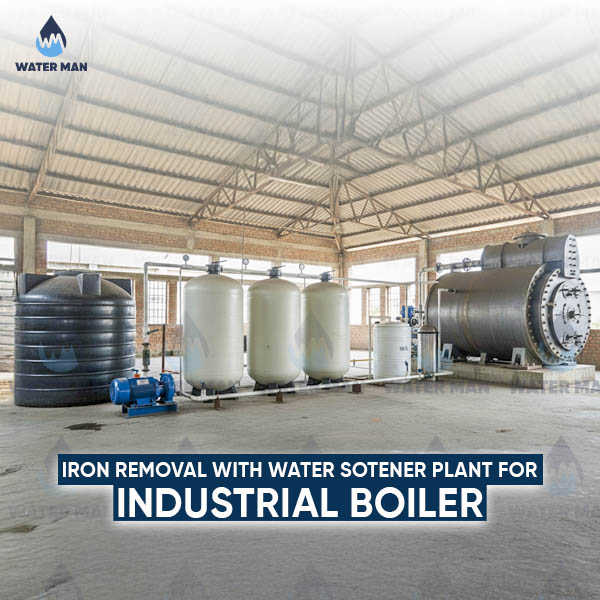

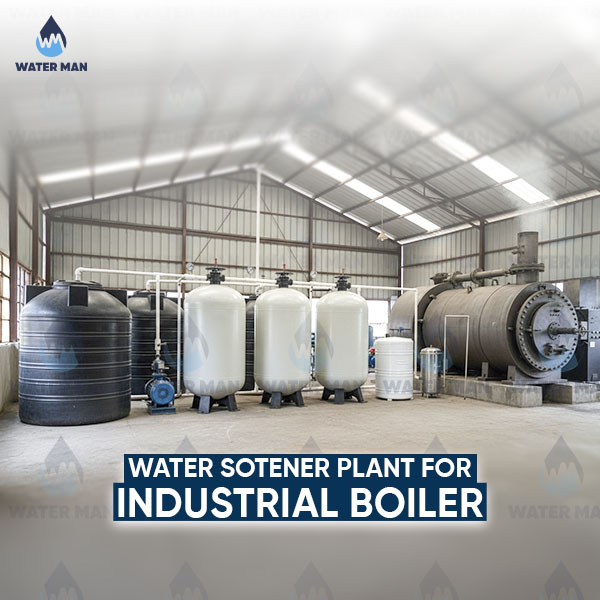

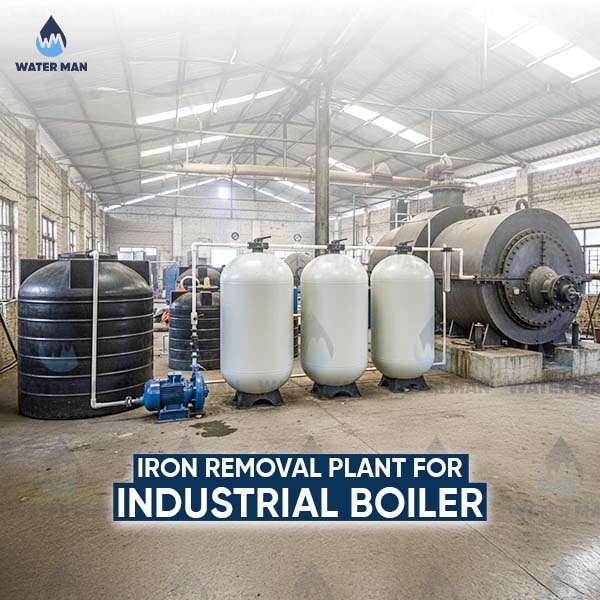

Iron Removal Plant with Water Softener Plant for Industrial Boilers in BD

An Iron Removal Plant (IRP) with a Water Softener Plant (WSP) is a comprehensive boiler feed water pretreatment system. It is specifically engineered to remove dissolved iron, oxidized iron, calcium, and magnesium hardness from raw water before it reaches the boiler. For industries in Bangladesh utilizing groundwater, this integrated solution is vital to prevent scaling, corrosion, and catastrophic tube failure.

By ensuring an iron-free and hardness-free water supply, this combined system protects your capital investment and ensures high-efficiency steam production.

Why Industrial Boilers Require a Combined Pretreatment System

Industrial boiler feed water must meet stringent quality standards to operate safely. Raw water typically contains iron, hardness minerals, and suspended particles that become highly reactive under high pressure and temperature.

The risks of untreated water include:

-

Composite Scaling: Iron forms an oxide sludge, while calcium/magnesium create a rock-hard scale. Together, they form a “thermal barrier” on tubes.

-

Efficiency Drop: A combined scale layer can reduce boiler thermal efficiency by 15% or more, leading to massive fuel waste.

-

Tube Failure: Scale causes localized overheating (hot spots), leading to metal fatigue, bulging, and eventually bursting.

-

Media Fouling: Without an IRP, iron will foul the water softener resins, rendering the softening process ineffective.

Integrated Roles in the Treatment Line

1. The Role of the Iron Removal Plant (IRP)

The IRP acts as the primary defense. It utilizes oxidation and specialized catalytic media to reduce iron levels.

-

Primary Filter: Removes larger rust particles and suspended solids.

-

Resin Protection: It is critical to remove iron first, as iron coats ion-exchange resins and RO water purifier membranes, causing permanent damage and high replacement costs.

2. The Role of the Water Softener Plant (WSP)

Once the water is iron-free, it passes through the softener. Using an ion-exchange process, it swaps hardness ions (Ca²⁺/Mg²⁺) with sodium ions.

-

Scale Prevention: Softened water ensures that boiler tubes remain clean and scale-free.

-

Reduced Blowdown: Cleaner water means fewer blowdowns, saving thousands of liters of treated water and significant heat energy.

Technical Datasheet: Combined IRP & WSP System

Our systems are custom-built to match your boiler’s capacity and your specific raw water analysis.

To achieve maximum protection, the system follows this professional configuration:

-

Raw Water Source

-

Feed Water Pump

-

Iron Removal Plant (Protects the Softener)

-

Water Softener Plant (Protects the Boiler)

-

RO / DM Plant (Optional for ultra-pure steam)

-

Boiler Feed Water System

Contact WaterMan BD

WaterMan BD is a leading provider of integrated industrial water solutions in Bangladesh. We serve the textile, pharmaceutical, and food & beverage sectors with high-performance systems and expert support.

-

Hassle-Free Setup: We provide full water purifier installation and system commissioning by senior engineers.

-

Authentic Spares: We maintain a ready stock of water treatment plant accessories, premium resins, and catalytic media.

-

Nationwide Support: Our dedicated water treatment plant service team is active across all industrial hubs to ensure zero-downtime operations.

Reviews

There are no reviews yet.