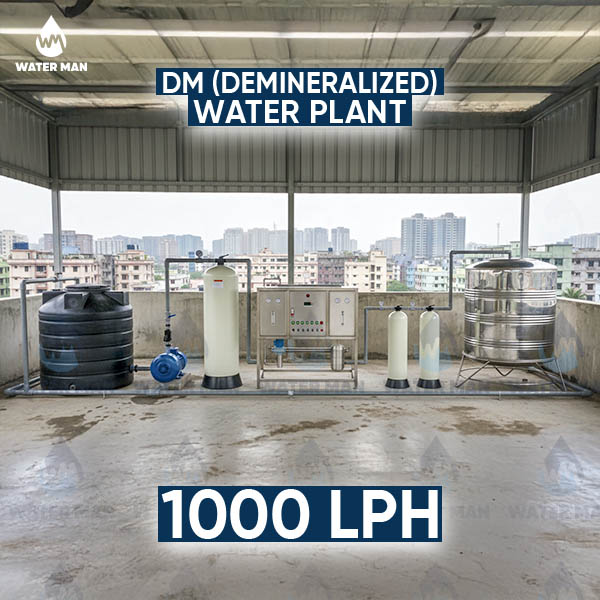

DM Demineralized Water Plant with RO Pre-treatment 1000 LPH for Industrial Purity

The DM Demineralized Water Plant 1000 LPH is a high capacity industrial solution designed to provide 100 percent mineral free water for large scale operations. By combining Reverse Osmosis or RO pre treatment with advanced ion exchange technology, this system ensures the highest level of chemical purity and low conductivity. As a premium household water purifier and industrial hybrid system, it is engineered to remove dissolved salts and minerals that can damage sensitive machinery or affect production quality.

Investing in an integrated RO and DM plant is a smart way to manage your water filter cartridge price in Bangladeshwhile providing laboratory grade water for pharmaceuticals, textiles, and power plants.

DM Water Plant with RO Pre-treatment 1000 LPH Performance Features

This system employs a specialized two stage scientific approach to guarantee absolute water demineralization and mineral removal:

-

RO Pre-treatment Stage: Utilizes high pressure membranes to remove 98 percent of total dissolved solids before the water reaches the resin beds.

-

Dual Bed Ion Exchange: Features high grade Cation and Anion resins that capture remaining ions to produce water with ultra low conductivity.

-

High Flow Rate Capacity: Delivers a massive 1000 liters per hour of treated water to meet the demands of large industrial processes.

-

Precision Monitoring Control: Equipped with real time conductivity and flow meters to ensure the output water meets strict technical standards.

-

Stainless Steel Frame Construction: Built on a heavy duty corrosion resistant frame for maximum durability in harsh industrial environments.

Key Benefits

-

Double Layer Protection: The RO pre treatment extends the life of the DM resins, significantly reducing the frequency of chemical regeneration.

-

Ultra Pure Water Quality: Effectively eliminates dissolved solids like Calcium and Magnesium to prevent scaling in boilers and cooling towers.

-

Cost Effective Production: Engineered for high efficiency and low power consumption, making it an economical choice for 24 hour operations.

-

Scalable Industrial Solution: Perfectly suited for the textile industry, beverage production, and large scale pharmaceutical manufacturing.

-

Automatic System Protection: Includes safety switches and pressure valves to protect the pump and membranes from operational damage.

-

Minimal Maintenance Design: Features a user friendly control interface and easily accessible filters for streamlined servicing.

Why Choose WaterMan

WaterMan BD is your leading provider of 100 percent authentic water treatment products in Bangladesh. When you purchase this 1000 LPH plant from us, you get:

-

Guaranteed Authenticity: We only supply high quality components with verified manufacturer technical specifications.

-

Professional Installation: Our water purifier service team ensures your plant is set up for maximum chemical efficiency.

-

Fast Delivery: Reliable shipping and dedicated technical support to your doorstep anywhere in Bangladesh.

-

Full Part Support: We carry a complete range of RO water plant accessories and high grade resins for your convenience.

Reviews

There are no reviews yet.