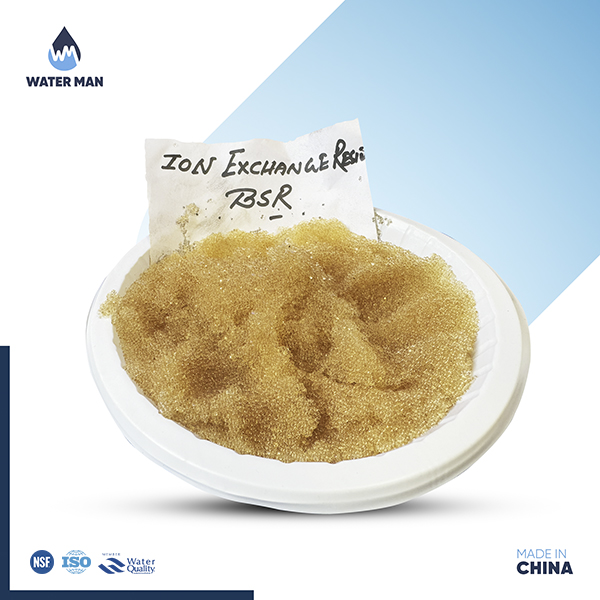

Description of BSR Cation Exchange Resin

BSR Cation Exchange Resin is a high-quality, sulfonated, polystyrene cation resin designed for a wide range of industrial applications. This premium- grade ion exchange resin is available in both sodium and hydrogen forms, packed as moist, durable, uniform spherical beads, lon exchange is a crucial unit operation that enables the separation of ionic species from liquid solutions, offering specific separation and concentration of target ions in the solid phase. What makes ion exchange particularly appealing is its ability to be reused through a regeneration process, ensuring cost- effective and sustainable water treatment solutions.

Applications:

Ion exchange plays a pivotal role in various industrial processes, including:

Metal Cation Recovery: Efficiently recover metal cations from solution.

Ion Mixture Separation: Separate mixed lonic species with precision.

Liquid Purification: Purify liquids for various applications.

Controlled Chemical Release: Enable controlled release of specific chemical species.

Salts Recovery: Recover valuable salts from solutions.

Wastewater Treatment and Purification:

BSR ion exchange resin also finds application in wastewater treatment and purification. It allows for the removal and potential recovery of ionic components from effluents before final discharge or reuse, ensuring compliance with water quality standards. This resin’s versatility extends to removing ionized organic molecules, such as water-soluble dyes, often resistant to conventional purification methods.

Ion Exchange Process:

The ion exchange process involves a solid phase (ion exchanger material) surrounded by a liquid phase containing the target solute. This process is based on the exchange of ionic species of the same electrical charge. Cation-exchange resins are used for separating positive ions, while anion- exchange resins are suitable for negative lons. These synthetic resins are specifically designed for various applications and are presented as spherical particles with cross-linked polymer structures and specific functional groups for selective ion exchange.

Storage and Safety:

Proper storage is essential for preserving resin quality. Store unused resin in its original, unopened packaging in a cool, dry area with a temperature range of 32-90°F (0-30°C). Safety precautions include avoiding eye contact, cleaning up spills promptly due to resin’s slippery nature, and handling with care.

Loading/Unloading Resins:

Various methods can be employed to load and unload ion exchange resins, depending on equipment design and site-specific procedures. Preliminary inspection, cleaning, and testing are essential steps before loading resins into vessels.

Cleaning Procedures:

For removing iron and manganese from cation resins, an air brushing system is recommended, particularly in water treatment applications. This system effectively removes insoluble particulate iron (crud) from the resin bed, ensuring optimal resin performance.

Conclusion:

BSR Cation Exchange Resin offers a premium solution for a wide range of industrial water treatment needs. Its versatility, efficiency, and reusability make it a valuable asset for various applications, ensuring cost-effective and sustainable processes. Proper storage and handling, along with thorough cleaning procedures, contribute to the resin’s longevity and effectiveness.

Reviews

There are no reviews yet.